设计规范:

设计制造:GB/T 12235, DIN EN 13709:2003

结构长度:GB/T 12221, DIN EN 558-1

连接尺寸:HG/T 20592, DIN EN 1092-1

压力-温度: GB/T 9131 ASME B16.34 HG 20592

试验-检验: GB/T13927 GB/T 9092 API 598

氦质谱检漏:API 602 MSS SP-117

应用:适用于精确控制气体、液体等介质工艺参数如压力、流量、温度、液位保持在给定值。特别适用于泄漏量要求高的场合。

设计特点:

1:流体通道呈S流线型、压降损失小,允许压差大,噪音小,符合环保要求。

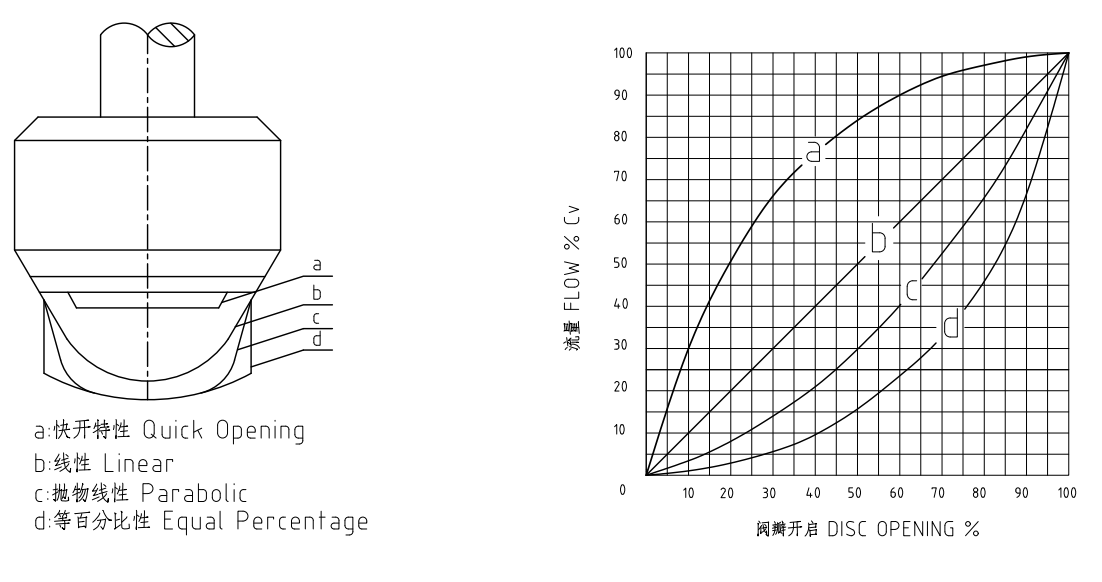

2:气动单座阀可调范围大,固有可调比为50。

3:活塞式薄膜外形的执行器更适宜高频繁的工作,寿命测试为100000次。

4:独有波纹管密封,提高使用寿命,并确保流量特性良好。

执行器:电动,薄膜型气动,活塞型气动

选配:限位开关,过滤器,电磁阀,应急手轮

Application: Suitable for precise control of gas, liquid and other media process parameters such as pressure,flow, temperature, level at a given value. Particularly suitable for leakageswhere a high level of leakage is required.

Design features:

1: fluid channel is S streamline, small pressure drop loss, allowable differential pressure, low noise, in line with environmental requirements.

2: Pneumatic single seat valve adjustable range, inherent adjustable ratio of 50.

3: Piston type film shape actuator is more suitable for high frequency work,life test is 100000 times.

4: Exclusive bellows seal to improve service life and ensure good flow characteristics.

Actuators: electric, diaphragm type pneumatic, piston type pneumatic

Options: limit switches, filters, solenoid valves, emergency handwheels